Automated selection of PCB traces for signal integrity analysis in high-speed digital systems

Simplifying PCB Trace Selection for Signal Integrity Simulation

|

| Simulation tab on Open Hardware Portal |

Hey there! Today, we’re diving into the world of PCBs (Printed Circuit Boards) and how Antmicro is making it easier to select traces for signal integrity (SI) simulations. If you're into electronics, you know how tricky high-speed digital interfaces like DDR or PCIe can get. These need carefully designed traces to keep signals clean and error-free.

Why Does This Matter?

In high-speed circuits, signals travel super-fast, and even tiny errors can mess things up. SI simulation helps us predict and fix potential issues before they cause problems. It's like a test run for your PCB design.

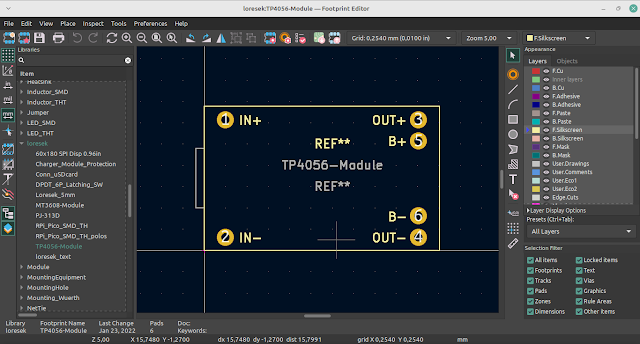

Meet gerber2ems

Antmicro’s been using a tool called gerber2ems. This nifty tool converts PCB files (from software like KiCad) into formats suitable for simulation with openEMS. This makes it possible to test complex designs like DDR5 memory modules and high-speed FPGAs more efficiently.

The New Automation Scripts

Previously, setting up these simulations was a bit of a hassle, done manually. Now, Antmicro’s created some cool wrapper scripts to automate the process. Here’s a rundown of how it works:

- Select Nets for Simulation: Choose the critical traces or differential pairs.

- Create Simulation Cases: Prepare the PCB slices and config files.

- Manual Adjustments: Tweak settings or port placements if needed.

- Export to 3D Mesh: Use gerber2ems to convert slices.

- Run Simulations: Fire up openEMS to simulate.

- Visualize Results: Get graphical insights into your simulation.

- Showcase Results: Share results on the Open Hardware Portal.

Making a PCB Slice

Using KiCad’s Python API, Antmicro’s script ‘si-wrapper slice’ creates PCB slices. These slices are sections of the board focusing on the selected nets. The slices are tailored to include relevant neighboring nets and components to ensure accurate simulation results.

Placing Simulation Ports

Simulation ports act as signal entry and exit points in the simulation. The script automatically places these ports at the right spots, but you can adjust if needed.

Simulation Configuration

The script generates a configuration file with all necessary parameters, which can be tweaked if the default settings don’t meet your needs.

Real-World Example: SO-DIMM DDR5 Tester

Antmicro applied this process to their SO-DIMM DDR5 Tester, a board that tests DDR5 and LPDDR5 memory interfaces. High-speed interfaces like these are prone to SI issues, so simulations are crucial. The team ran simulations on various net configurations, showing how different settings impact signal integrity.

Visualizing the Results

The results included impedance charts and S-parameters, helping to confirm that the design was spot-on. These insights are visualized on the Open Hardware Portal for easy access and understanding.

Why It’s Cool

|

| Animation of the simulated signal |

Antmicro’s approach brings a streamlined, automated workflow to PCB design, making it less of a headache to ensure signal integrity in high-speed designs. Their open-source tools and scripts are a game-changer for developers, providing robust testing and verification before manufacturing.

Wrap-Up

Antmicro’s innovations in SI simulation help designers create more reliable and efficient PCBs. If you’re into hardware design and want to simplify your workflow, check out their tools and services. Click here for more info.