Step-by-Step Guide to Routing Differential Pairs in KiCad

Routing differential pairs is a key aspect of designing high-speed PCBs, as it plays a vital role in maintaining signal integrity. KiCad simplifies this process by providing tools such as differential pair routing, length tuning, and skew matching. These features help ensure that both traces are routed with identical length, width, and spacing to reduce signal interference.

In this KiCad tutorial, we’ll guide you through the steps to successfully route differential pairs, focusing on accurate signal timing, length matching, and skew control.

Routing Differential Pairs in KiCad

Step 1: Select the Correct Layer

Before you begin routing, make sure you are on the correct layer. If you want to route on the bottom layer, navigate to the layer selector and choose Bottom.Cu.

Step 2: Choose the Differential Pair Tool

Head to the top menu and select Route –> Route Differential Pair. This will activate the differential pair routing mode.

Step 3: Start Routing the Traces

Click on the starting point of your differential pair, which is usually a pad or via, and begin routing the traces. As you guide them along the desired path, KiCad will automatically maintain the correct spacing between the two traces, ensuring proper signal integrity.

Step 4: Verify the Skew

Make sure the skew (the difference in length between the two lines of the differential pair) stays within your specified tolerance, which is usually around 5 mil. You can fine-tune this in the rule settings, as explained in the section on matching skew between traces.

For the last part of the connection, you can simplify the process by using a single trace to complete the routing.

Length Tuning the Differential Pair

Length matching is essential for maintaining signal integrity in high-speed PCB designs. Here's how to length-match differential pairs in KiCad.

Step 1: Define Length-Matching Rules

Before you begin tuning, it’s important to set the length-matching parameters. Open the Board Setup dialog by either clicking the Board Setup icon in the top toolbar or going to File –> Board Setup. Here, you can adjust the rules for length matching to ensure optimal signal performance.

In the Board Setup, click on the Length-Tuning Patterns section. Here, you'll set the parameters for single-track, differential pairs, and differential pair skews.

Define the amplitude and spacing for serpentine patterns—ideally, set the spacing to 3W, where W is the width of the trace. Additionally, choose the corner style, such as Fillet for smoother curves.

When setting spacing, note that it’s calculated edge-to-edge between the traces, not center-to-center, to achieve the accurate 3W spacing.

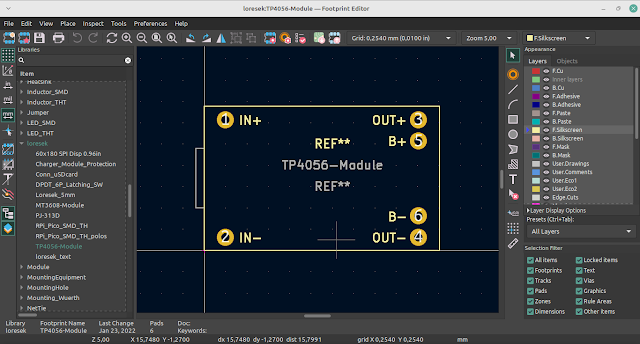

Step 2: Create and Assign a Differential Pair Class

Next, you'll need to create a new net class specifically for your differential pairs. Set the trace width and clearance according to your design requirements. Afterward, configure the differential pair width and gap, which refers to the clearance between the traces.

To assign this class to your differential pairs, go to the Net Classes section in the Board Setup and assign the newly created class to the differential pairs. This ensures the correct rules are applied during routing.

Ensure that the minimum track width in the Constraint Manager is equal to or less than the differential pair width. If this setting isn’t configured correctly, KiCad may not apply the routing rules properly, which could result in errors during the routing process.

Step 3: Calculate and Set Length Matching Tolerances

After routing the traces, check the length of each trace in your differential pair.

Identify the longest trace and use its length as the reference to set your custom length-matching rules under Design Rules in the Board Setup.

For instance, if the longest trace is 1661.25 mil, set the maximum length to 1662 mil with a tolerance of ±10 mil. This means the minimum length will be 1652 mil. All traces within the differential pair class will be checked against these length limits, and any trace that falls outside this range will trigger an error.

Step 4: Perform Length Tuning

With your rules in place, use the length tuning tool to adjust the shorter trace to match the reference length. Navigate to Route —> Tune Length of a Differential Pair from the menu to begin fine-tuning. KiCad will automatically add serpentine patterns to the shorter trace to ensure both traces meet the length requirements.

The length tuning tool will show the current length of the trace, and as you drag to adjust it, the tool will continuously update the length to ensure it meets your minimum and maximum requirements. Once the trace length falls within the specified range, click to finalize the tuning.

After you've finished tuning, double-check that all differential pairs comply with the length-matching criteria. If any traces still don’t match the required length, KiCad will flag them, allowing you to go back and make further adjustments.

For a quick cost estimate of your PCB design without leaving KiCad, you can install the KiCad Quote Plugin.

Matching Skew Between Traces

Skew matching is a crucial part of working with differential pairs. It ensures that the signals on the positive (P) and negative (N) traces stay in sync. KiCad offers tools and customizable rules to help achieve accurate skew matching.

Step 1: Open Board Setup

Go to File —> Board Setup or click the Board Setup icon in the top toolbar to access the settings needed for skew matching.

Step 2: Establish Skew Matching Rules

In the Board Setup dialog, navigate to Design Rules —> Custom Rules. Here, you can set the skew constraint specifically for matching the traces within differential pairs.

For example, you might configure the minimum skew to -5 mil and the maximum skew to +5 mil. This means the length difference between the positive (P) and negative (N) traces should not exceed 5 mil in either direction. If the longest trace in the pair measures 100 mil, the shorter trace must fall between 95 mil and 100 mil. The rule will individually check each trace, ensuring neither exceeds the defined skew limits.

Ensure that the skew rule is applied only to coupled differential pairs. In the Custom Rules section, specify that the rule should only apply to traces belonging to the same differential pair.

Step 3: Tune the Skew of the Differential Pair

Once your skew constraints are set, you can begin tuning the skew. Click on Route —> Tune Skew of Differential Pair. This feature allows you to adjust the trace lengths while staying within your defined skew tolerance, ensuring optimal performance for your differential pair.

Click on the differential pair to check the current skew measurement. If the skew exceeds your specified limit, simply adjust the trace by dragging it to decrease the length difference and align it more closely with the other trace.

If you're working with multiple differential pairs, make sure to space them at least 5W apart, where W represents the width of the differential pair. This spacing helps maintain signal integrity and reduces the risk of interference between the pairs.