Kicad Project Cost Reduction Strategies: How to Keep Your Projects On Budget

When designing and manufacturing a product, a PCB can quickly become one of the most expensive components of the entire product, so lowering the PCB cost can be one of the major factors that can be proven beneficial for lowering the overall production cost. The PCB cost can be significantly reduced by reducing the PCB size, selecting appropriate components, and implementing appropriate design techniques. As a result, in this article, we will discuss the most common PCB cost-cutting techniques that you can use when designing and fabricating your PCB.

Here are some strategies to reduce the cost of a KiCAD project:

Reuse components

By reusing components that have already been designed, tested, and proven, you can save time and reduce costs associated with designing and testing new components.

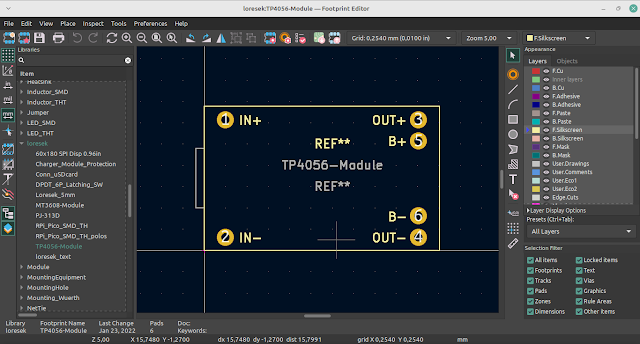

To create reusable KiCAD components, you need to follow these steps:

- Design the symbol of the component using the "Symbol editor" tool in KiCAD.

- Create a footprint for the component using the "Footprint editor" tool in KiCAD.

- Save the symbol and the footprint in a library file.

- Add the library file to the project using the "Eeschema" tool and the "Pcbnew" tool.

- Place the component in the schematic and assign it to the footprint.

- Repeat the steps for each component you want to create.

- Save the library file for future use.

It is important to keep your components and libraries organized and well documented so that you can easily find and reuse them in future projects.

Simplify the PCB design

Reducing the overall complexity of the PCB design can reduce the number of components needed and make the manufacturing process more efficient. This can result in cost savings. Below is the example how to simplify the PCB design:

- Minimize the number of layers: Reduce the number of layers used in the PCB design to simplify the manufacturing process and reduce costs.

- Use standard components: Choose commonly used components that are widely available, rather than custom components, to simplify the design and reduce the risk of obsolescence.

- Avoid unnecessary routing: Use the shortest possible routing paths to reduce the amount of copper trace required and simplify the design.

- Optimize component placement: Place components in a logical and organized manner to minimize the amount of trace routing required and simplify the design.

- Use test points: Include test points on the PCB design to facilitate testing and debugging, which can simplify the process of finding and fixing faults.

- Utilize design rules: Adhere to established design rules to simplify the design and ensure that the PCB is manufactured according to industry standards.

- Make use of design software: Use a PCB design software that has built-in design rule checking and component libraries to simplify the design process.

Want more??? Here the another article how to simplify the PCB design by Altium Designer.

Choose low-cost components

Researching alternative components that are lower in cost but still meet the requirements of the design can help reduce the overall cost of the project.

Use open-source tools

KiCAD is a free, open-source electronic design automation tool that can help reduce the costs associated with proprietary software. In addition, using open-source libraries, simulation tools, and other resources can also help reduce costs.

Outsourcing services

Outsourcing certain aspects of the design, such as board assembly, can help reduce costs associated with labor and equipment. This can be especially useful for small businesses or individuals who do not have the resources to assemble boards in-house. Some recommendation outsourcing services is like PCBWay and JLCPCB.

here are some tips for outsourcing PCB assembly services at PCBWay/ JLCPCB:

- Choose the right assembly service: PCBWay/ JLCPCB offers various assembly services such as SMT, THT, and BGA assembly. Make sure you choose the right assembly service that meets your requirements and specifications.

- Provide clear specifications: Clearly specify the requirements for your board, including the components, their placement, and the assembly process. This can help ensure that the assembly service meets your expectations.

- Provide high-quality files: Provide high-quality Gerber files, BOM (Bill of Materials), and any other relevant files to ensure that the assembly service has the information needed to assemble your board correctly.

- Communicate effectively: Communication is key when outsourcing assembly services. Be sure to clearly communicate your requirements and expectations to the assembly service provider to ensure that the process goes smoothly.

- Check quality control: PCBWay/ JLCPCB offers quality control services to ensure that your boards are assembled correctly. Be sure to review the quality control process and requirements to ensure that your boards meet your specifications.

- Consider lead time: Consider the lead time for assembly when outsourcing services. PCBWay/ JLCPCB provides a range of lead times to choose from, so make sure to choose the one that meets your timeline requirements.

By following these tips, you can effectively outsource your PCB assembly services at PCBWay/ JLCPCB and ensure that your board is assembled correctly and within your budget.

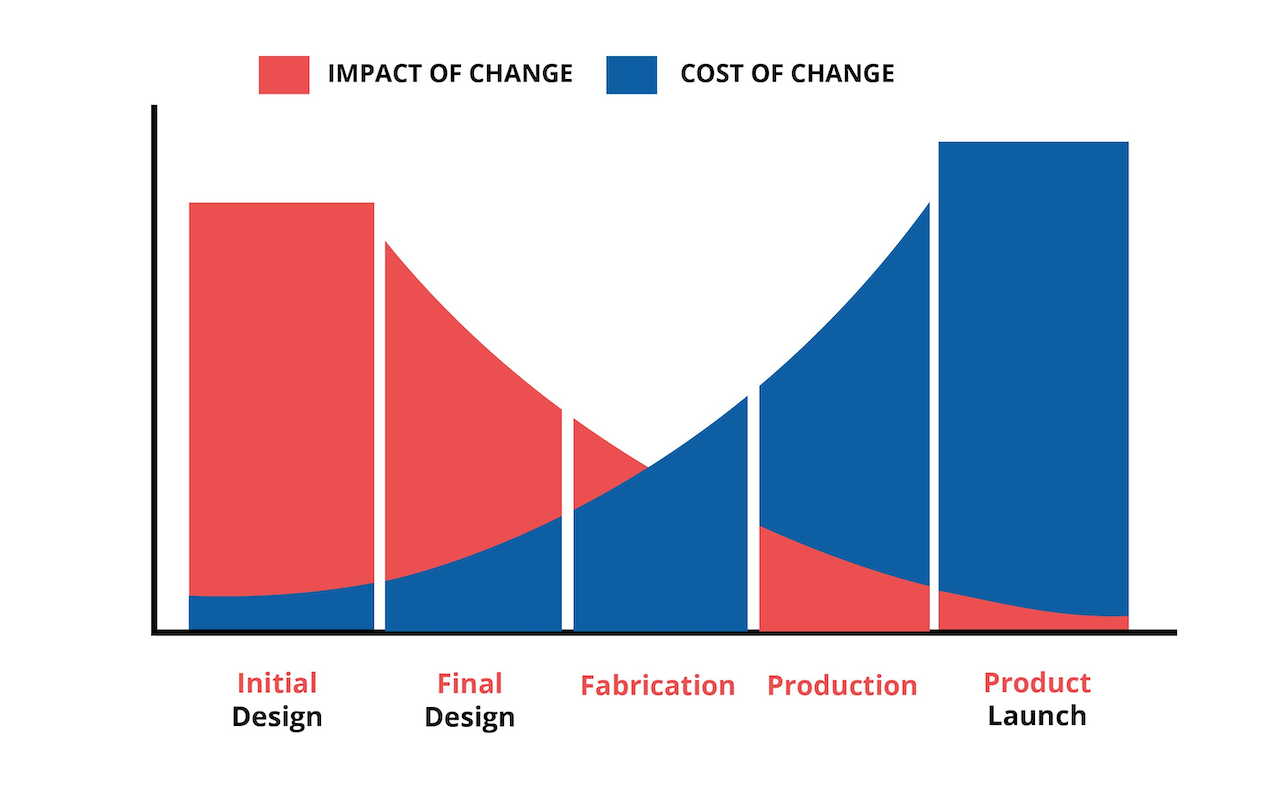

Implement design for manufacturing (DFM) principles

Proper planning and design practices, such as DFM, can help reduce costs associated with manufacturing and assembly. This can include reducing the number of components, optimizing board layout, and considering the manufacturing process in the design.

Collaborate with suppliers

Engaging with suppliers early in the design process can help ensure that components and manufacturing processes are optimized for cost. This can include working with suppliers to select the most cost-effective components and negotiating better prices for components and services.

By following these strategies, you can keep your KiCAD project within budget and deliver a high-quality product.